According to the frequency, output current and torque of the inverter, the brake release command will be output. When starting and stopping, keep the necessary torque to stabilize the cargo, and open the holding brake, and start and stop smoothly without slipping the hook to prevent the cargo from sliding down.

By the limit sensor input can prevent the hook from overtraveling and excessive hoisting.

Through the light load speed-increasing function, the best running speed matching the load can be achieved. When the load is light, it allows automatic speed increase and improves efficiency, no auxiliary hook design is required, which can shorten the operating period of the crane with a long head.

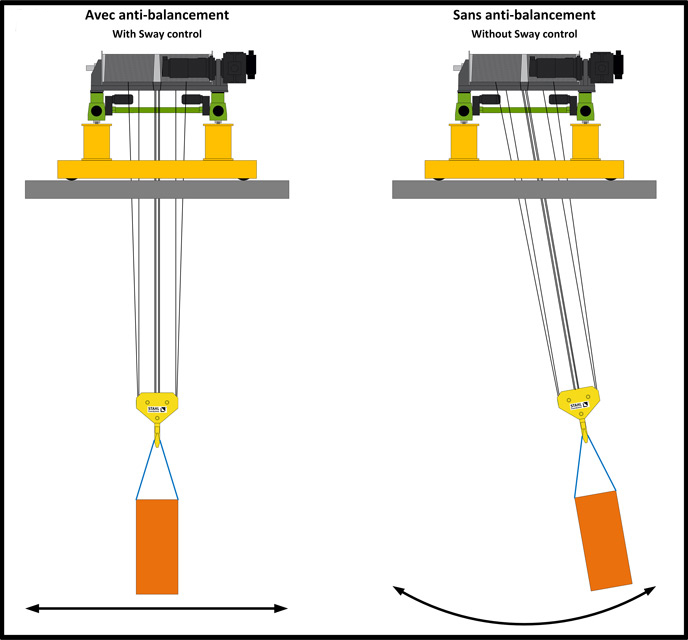

♦ Intelligent anti-sway function

With built-in anti-sway function, so can suppress the shaking of the goods during translation. Since the load does not sway, it can be laid down faster, which is beneficial to shorten the operating cycle.

♦ Synchronous control function

High-precision control can be carried out according to the operating conditions of the machine, to achieve stable walking and operation. It can also equalize the load of each inverter, and can also eliminate the position deviation when two hoists are hoisted at the same time through closed-loop synchronous control.

♦ Parameter macro function

The function to select the purpose according to the crane action. Just select hoist, long travel, trolley and other uses, you can automatically set the necessary and unnecessary functions to be valid or invalid. The best parameters can be set simply for different purposes.

♦ Rope length detection function

The height information of the hook can be seen in the cab just by the inverter. When the wire rope reaches the set length, the collision with the lifting drum can be avoided by reducing the ascent and descent speed.

♦ Rapid deceleration function

By inputting a quick stop command through the terminal, it can perform rapid deceleration near the target position.

♦ Load holding function

When stopped, the load can be kept at the current position through zero-speed control. Close the brake when it is stable. (Valid closed loop)

♦ Overload detection function

Limit the operation of the inverter when the load exceeds the preset upper limit. Alarm display and lifting device stop can be set to prevent danger caused by overload operation.

♦ Maintenance reminder

Count the number of brake commands. It can be used as reference data for brake maintenance such as system inspection and parts replacement.

♦ Over torque detection function

The torque rise value is detected when the cargo accidentally contacts other objects. At this time, the motor can be automatically stopped to prevent accidents and improve safety.

♦ Self-tuning motor parameters

It can accurately identify asynchronous induction motors and achieve high-performance vector control; it can achieve accurate setting of motor parameters of long-distance power cables under load, and can automatically discriminate encoder signal directions under encoder conditions, simplifying the debugging process.

♦ Smart cloud application

The frequency inverter can be managed in parameters in the cloud by wireless connection, effectively using smart phones, tablets and other new equipment to manage crane applications.

♦ Brake failure detection

When the stop brake is valid, the encoder is used to detect whether the brake is invalid. If it fails, the inverter is automatically started to maintain torque to prevent accidents. (Valid closed loop)

► User Manuals